IIT-M tech to take part in int comp

S Vishnu Sharma, INN/Chennai, @Svs037

Indian Institute of Technology-Madras (IIT-Madras) is a place where there is no end to innovation. The latest one displayed was a proof in this regard. Avishkar Hyperloop team unveiled Hyperloop pod on 14 June.

This will also compete in competition organised by SpaceX, the American company into aerospace manufacturing and space transportation. Avishkar Hyperloop is a student team from Centre for Innovation (CFI) at IIT-Madras.

It is worth recollecting that the team is working with a vision to develop technologies for future high speed transportation.

Professor with Aerospace Engineering department and faculty advisor with Avishkar Hyperloop Dr S R Chakravarthy students have worked hard for this project. They took care at every stage to ensure the the outcome is the best at every stage.

Elon Musk, founder of SpaceX, proposed the idea of Hyperloop to the world in 2013. His company SpaceX organizes the Hyperloop Pod Competition to accelerate the development of functional prototypes and encourage student innovation.

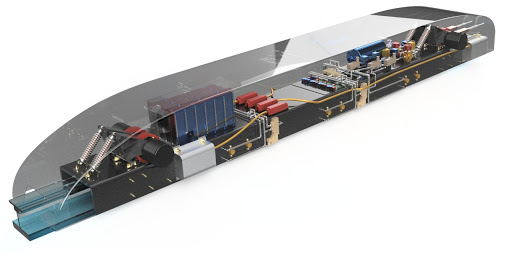

Hyperloop is a high speed train that travels in a near vaccum tube. As air resistance comes down in the vaccum tube, train can travel at a speed of 1000kmph.

Teams taking part in the competition build a subscale prototype transport vehicle to demonstrate the technical feasibility of various aspects of the Hyperloop concept.

The final rounds of the competition takes place in the headquarters of SpaceX in United States. Whoever designs hyperloop that is fastest emerges winner in the competition. Should we have this train the day is not far when distance between the national capital to Chennai could be covered in two hours.

The Pod developed by Avishkaar Team spans about three metres in length and weighs around 120 kgs. The electric propulsion employs BLDC motors and a wheel drive.

The team started the design by brainstorming on how the pod would be built, beginning with vehicle kinematics and dynamics, motors, power system and braking, stability, and finally designing the CFRP chassis and structures.